Features of PTFE Bearings: -

Bearings operate dry, no stick slip, require no lubrication and hence no maintenance throughout the working life.

Designed for the working life of structure. No replacement required, hence economical in the long run.

I) Important Properties of PTFE which make it suitable as Bearing material:

1. PTFE is a thermo-plastic material and occupies special place among plastics used in bearings running without lubrication.

2. Due to its low surface tension, PTFE belongs to non-wetted materials. It does not absorb water.

3. Chemically it is a very stable material and is immune to almost all kinds of weathering and chemical actions.

4. Thermally it is also very stable and has operating temperature range from -200 C to +200 C.

5. The chemical and thermal stability of molecular structure is mainly due to very stable carbon – carbon and carbon – fluorine bond which, as one of the strongest single bond, is capable of forming long polymerization chain.

II) Salient Technical Features of PTFE Bearings:

1. Both PTFE and stainless steel are highly corrosion resistant and offer excellent weathering properties, therefore initial coefficient of friction i.e. 3% is maintained throughout the operating life of bearings. However, in case of roller/rocker bearings the friction increases as rollers become old and corroded.

2. A roller bearings has the facility to rotate about a single axis only. Hence, it is very essential to ensure that axis of rolling is tangential to the axis of movement.

Whereas in case of PTFE bearings expansion is radial from a fix point.

3. The center of pressure in sub-structure changes in case of roller bearings due to sliding. However, in PTFE bearings the same remains constant ever under extreme movements of super structures.

4. The PTFE bearings would be cheaper in price as compared to roller/rocker bearings. Also, they are compact in size and much smaller in total height.

5. PTFE bearings provide greater flexibility for movements and rotations. They can accommodate any amount of movement and rotation.

6. Neoprene bearings, although for smaller capacity are cheaper in initial cost, need replacement after about 25 to 30 years. This involves cost of replacing bearings and lifting the super-structure. However, PTFE bearings are designed to last the life of structure and hence economical in the long run.

7. PTFE bearings are ideally suitable for continuous structure and large spans where expansions and rotations are large. The NEOPRENE design for such case would prove bulky and expensive in initial cost also.

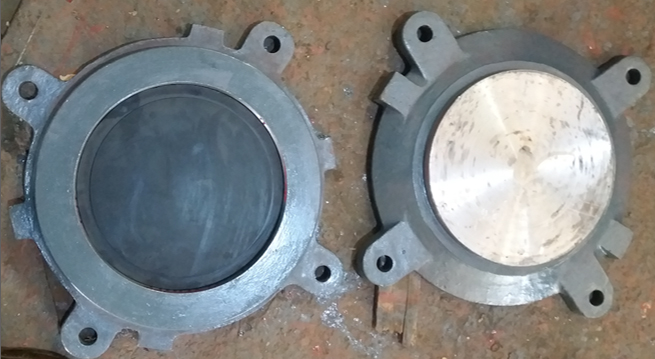

Sliding POT - PTFE Bearing

We are counted among the leading manufacturers, suppliers and exporters of a wide array of Pot PTFE Bearings. The material that is used for manufacturing these bearings is sourced from trustworthy and reliable vendors of the market. In addition to this, we customize these bearings on the basis of the specifications detailed by customers.

Fix Type POT - PTFE Bearing

A type of pot bearing which bears the vertical load and transmits horizontal force in any direction and allows rotation about any axis in horizontal plane without permitting any movement in horizontal plane.

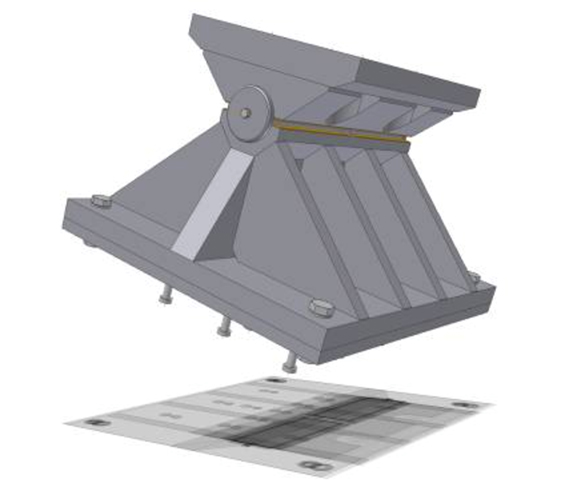

Metalic Guide Bearing

A Metallic Guide Bearing of a sliding assembly with restraint along a desired direction to bear & transit horizontal force and capable of allowing movement in a direction perpendicular to the direction of horizontal force. These Metallic guide bearings are capable of allowing rotation only about an axis perpendicular to the plane of sliding. Metallic Guide bearing cannot bear or transmit any vertical load. These Metallic Guide Bearings can be availed at industrial leading price.

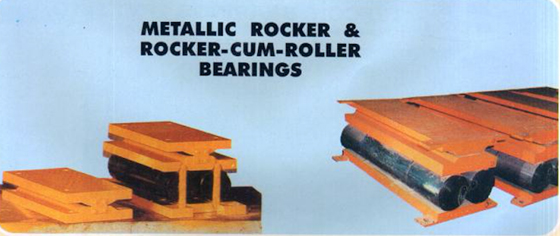

Roller - Rocker Bearing

A rocker bearing is a type of expansion bearing that comes in a great variety. It typically consists of a pin at the top that facilitates rotations, and a curved surface at the bottom that accommodates the translational movements. Rocker and pin bearings are primarily used in steel bridges.

Roller - Cum - Rocker Bearing

Owing to our expertise in this field, we are offering Rocker-Cum-Roller Bearings which ideally facilitate safety to structure for long time. Manufactured using premium quality raw material and advanced technology, these bearings are also equipped with one or more rollers of steel along with a rocker arrangement which permits a longitudinal and rotational movement. Moreover, these bearings are widely acknowledged for their features such as dimensional accuracy and rigid construction.

Testing of POT - PTFE Bearing

Testing of POT - PEFE Bearing are used to solve the problems of movement caused due to temperature change and differential material thermal expansion, settlement and natural forces encountered by high winds and even seismic activity.

A Testing of POT - PEFE Bearing comprises an upper element and a lower element, which operate by sliding against one another. The upper element is generally larger than the lower element by the amount of the anticipated movement. This ensures that the lower element is subjected to uniform load throughout motion and excludes foreign matter from the sliding interface.

Typical applications include construction, bridge bearings, pedestrian footbridges, storage tanks & structure expansion, power plants, Cooling tower and movement joints.